guides?id=6

Considerations in Hazardous areas

Design and equipment selection for use in hazardous areas will be influenced by :-

- the area classification

- the gas (or dust) group

- the temperature classification and equipment selected providing an appropriate type of protection

As stated above, this document focuses on the international standards developed especially for the electric heat tracing, IEC62395 - for Safe Industrial locations and IEC60079-30 - for Hazardous locations.

Registered Users have access to much more information in this section. Click the below accordions for an extract.

Area Classification

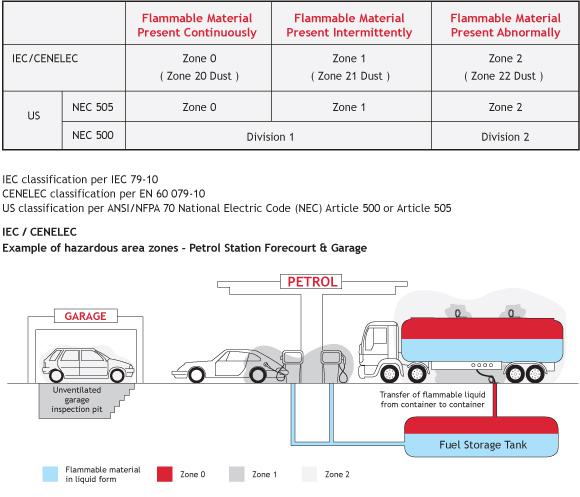

The probability of explosive conditions being present is defined by zone classification

- Zone 0 may have explosive gas-air mixture present continuously or for long periods. Heat tracing is rarely, if ever, used in Zone 0 areas.

- Zone 1 may have explosive gase-air mixtures present in normal operation.

- Zone 2 may have explosive gas-air mixture present only under abnormal conditions.

North American hazardous locations are categorised in Divisions rather than Zones. As stated above, IEC60079 and IEEE515 are being harmonised as a dual-logo standard. Therefore ETHIC's members product approvals will often cater for both Division and Zones.

Gas Groups

Gas Groups relevant to heat tracing in hazardous locations are :-

- IIA - Acetone, benzene, butane, ethane, methane, propane, etc.

- IIB - Ethylene, towns gas, etc.

- IIC - Acetylene, hydrogen